Modular nano confined electro catalytic oxidation equipment

1、 Equipment introduction:

The modular nano confined electro catalytic oxidation equipment is an intensive and efficient wastewater treatment equipment, which integrates decarburization, denitrification, complex breaking, precious metal reduction and other functions. The equipment is simple, small in size, small in area, only consumes clean energy and power, and has strong applicability. It is an environment-friendly and resource intensive environmental protection equipment.

2、 Equipment principle:

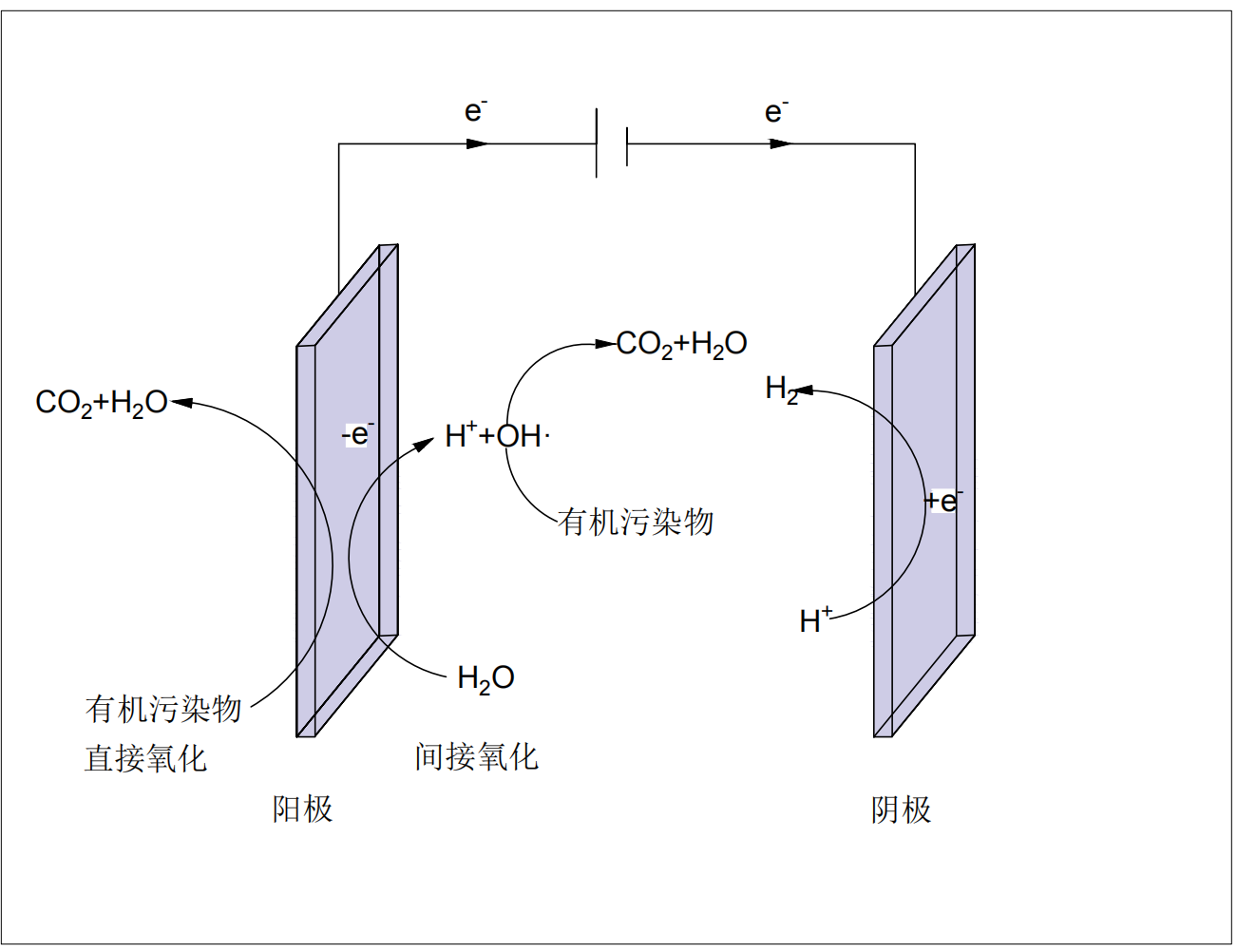

Under the action of external electric field, most pollutants are directly oxidized due to the limited catalytic effect of nano anodes; A small part of pollutants are indirectly oxidized by intermediate products (such as · OH and other free radicals) with strong oxidation generated by anodic reaction. At the same time, the reduction reaction of nitrate and (heavy) metal ions will also occur at the cathode, realizing denitrification and recovery of metal elements.

3、 Equipment features:

1.Modular design:

The number of modules shall be determined according to the water volume and water quality, which is convenient for installation;

2.Fully automatic operation:

Small size, simple and easy operation, less maintenance, high efficiency, and unattended operation;

3.Green and pollution-free:

It only needs to consume clean energy and electricity, without consuming a lot of chemicals, and will not cause secondary pollution;

4.Wide application scope:

According to the characteristics of different types of wastewater, the equipment structure can be flexibly adjusted and the process parameters can be optimized.

4、 Equipment suitability:

1.Toxic and harmful organic wastewater, high chlorine organic wastewater and other internationally recognized refractory wastewater:

The treatment effect is excellent, and the COD removal rate can reach more than 95%.

2.Upgrading and reconstruction of direct drainage:

It can ensure that the COD of external drainage reaches Class I B standard.

3.Heavy metal organic complex wastewater from leather, printing and dyeing industries:

The oxidation and collateral breaking, combined with oxidation and reduction, chemical precipitation, flocculation and sedimentation and other processes, can ensure that the content of heavy metals in the treated wastewater meets the discharge requirements, and can recover heavy metal sludge for resource utilization.

Related product technology

Official Accounts

Contact

Tel:0573- 88898389

Fax:0573-88860388

E-mail:zyhuanbao11@163.com

Add:No.296 Huaye Road, Fengming Street, Tongxiang City

Copyright © 2021 Zhejiang Zhiyuan Environmental Technology Group Co., Ltd. All Rights Reserved