Glass fiber composite pipe dry process integrated modular exhaust gas treatment equipment

1. Introduction

With the development of industry, environmental pollution has become more and more serious, especially the combustion of various industrial kilns and boilers, which are important sources of pollutants transporting pollutants to the atmosphere. Because air pollution has caused great harm to the earth environment for human existence, the global control of air pollution has become more and more stringent, and emission standards have been continuously improved. At present, the flue gas desulfurization, denitrification and dust removal system in the industry is a simple combination of independent systems. It has independent equipment and control systems. The entire set of desulfurization, denitrification and dust removal system has huge hardware and software and occupies space, and it also needs to be at the end Adding de-whitening equipment has disadvantages such as large investment, difficult management, low efficiency, and high operating cost. Therefore, our company designed and developed a modular exhaust gas treatment equipment for fiberglass composite pipe dry method integration and put it into actual engineering projects. It has obtained good environmental benefits and won the honor of "the first set" in Zhejiang Province and the key scientific and technological project of Tongxiang City. .

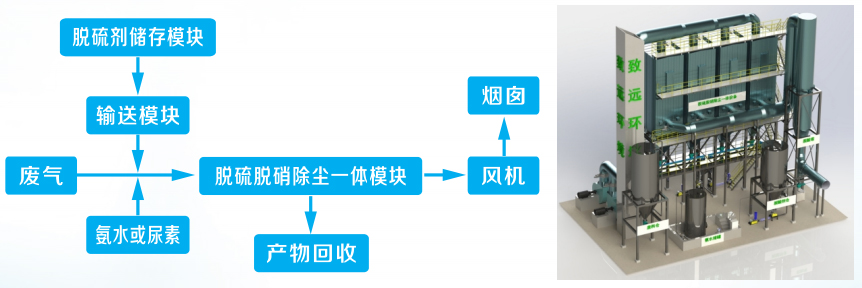

2. Process flow chart

3. Technical advantages

1. The system is single and uncomplicated, occupies less space, less investment, less maintenance, and can realize fully automatic unmanned operation.

2. The glass fiber composite pipe can withstand a high temperature of 750°C, which has a wider application range than a cloth bag (usually less than 200°C) and a higher dust removal efficiency, which can reach less than 5mg/m³.

3. The catalyst in the glass fiber composite tube is nano-particles uniformly distributed in the glass fiber tube wall, the catalyst contact area is large, the reaction time is increased, the removal efficiency is maximized, the irregular fiber labyrinth structure, when gas molecules pass, increase In addition to the touch frequency, the denitration efficiency is as high as 95%.

4. The catalyst in the glass fiber composite tube has a long service life, generally up to 3 years or even 5 years.

5. Since the amount of ammonia or urea sprayed is very small compared to the amount of waste gas, it immediately evaporates into gaseous water and ammonia when entering the waste gas. The temperature of the waste gas discharged through the chimney is above 150℃, so there is no "white smoke" and aerosols. Pollution phenomenon.

5. In the whole process, the exhaust gas working condition temperature is above 150℃, no sewage is produced, and there is no corrosion of equipment and pipelines.

7. The equipment can be designed with standard modularization, the equipment production cycle is shortened, and the on-site installation is convenient and time-consuming.

8. High treatment efficiency, no secondary pollution.

4. The main performance indicators

1. The sulfur oxide removal rate can reach more than 95%.

2. The removal rate of nitrogen oxides can reach more than 95%.

3. The removal rate of hydrogen chloride can reach over 97%.

4. The removal rate of hydrogen fluoride can reach more than 98%.

5. The removal rate of dioxin can reach more than 99%.

Related product technology

Official Accounts

Contact

Tel:0573- 88898389

Fax:0573-88860388

E-mail:zyhuanbao11@163.com

Add:No.296 Huaye Road, Fengming Street, Tongxiang City

Copyright © 2021 Zhejiang Zhiyuan Environmental Technology Group Co., Ltd. All Rights Reserved