Waste heat drying sludge equipment

1. Process introduction

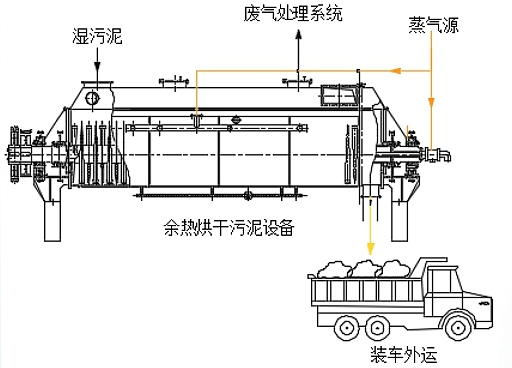

The sludge enters the waste heat drying sludge equipment, in which steam is used as the heat source to dry the sludge. The hollow shaft inside the equipment is densely arranged with wedge-shaped hollow blades, and the steam flows through the blades through the hollow shaft. The heat transfer area in the effective volume is large. The steam passes through the rotary joint and flows through the shell jacket and the hollow stirring shaft. The hollow stirring shaft has different internal structures according to the type of heat medium to ensure the best heat transfer effect. While the paddle and jacket are heated by steam, the upper part of the discharge port is simultaneously dehumidified, which greatly increases the drying strength of the equipment.

The evaporated water is taken out of the dryer by the dehumidifier fan and enters the subsequent exhaust gas treatment system. The steam pipeline is equipped with a steam regulating valve to adjust the size of steam to adjust the amount of sludge drying. The waste heat drying sludge equipment can reduce the moisture content of the sludge from 75% to less than 20%, and the dried sludge is loaded and shipped out.

2. Process flow chart

3. Features

1. Low energy consumption: due to indirect heating, there is no large amount of air to take away the heat, and the outer wall of the dryer is provided with an insulation layer, so the heat loss is very small;

2. High heat utilization rate;

3. Low cost: There is a huge heat transfer surface in the unit effective volume, which shortens the processing time; the size of the equipment becomes smaller, and the area is reduced;

4. Wide range of processing materials

5. Small environmental pollution.

Related product technology

Official Accounts

Contact

Tel:0573- 88898389

Fax:0573-88860388

E-mail:zyhuanbao11@163.com

Add:No.296 Huaye Road, Fengming Street, Tongxiang City

Copyright © 2021 Zhejiang Zhiyuan Environmental Technology Group Co., Ltd. All Rights Reserved